In this blog post, we delve into 5 usable tips for jaw crusher that can elevate the performance and longevity of your jaw crusher. Whether you are a seasoned operator or new to the world of crushing technology, these insights will empower you to make informed decisions, conduct proactive maintenance, and maximize the efficiency of your jaw crusher.

The jaw crusher, a fundamental component in the mining and aggregate industries, plays a pivotal role in reducing large rocks into smaller, more manageable pieces.

As a workhorse of industrial operations, the efficiency and reliability of a jaw crusher can significantly impact overall production. To harness the full potential of this essential equipment, it is crucial to implement effective tips and strategies for optimization.

From routine checks to adjusting settings and monitoring wear patterns, these tips are designed to enhance the operational prowess of your jaw crusher, ensuring it operates at its peak efficiency.

Let’s embark on this journey to unlock the secrets of jaw crusher optimization and pave the way for smoother, more productive operations. Before that, let me introduce Craftsmen Industries as a best jaw crusher manufacturer in Udaipur.

Craftsmen Industries: As a best jaw crusher manufacturer

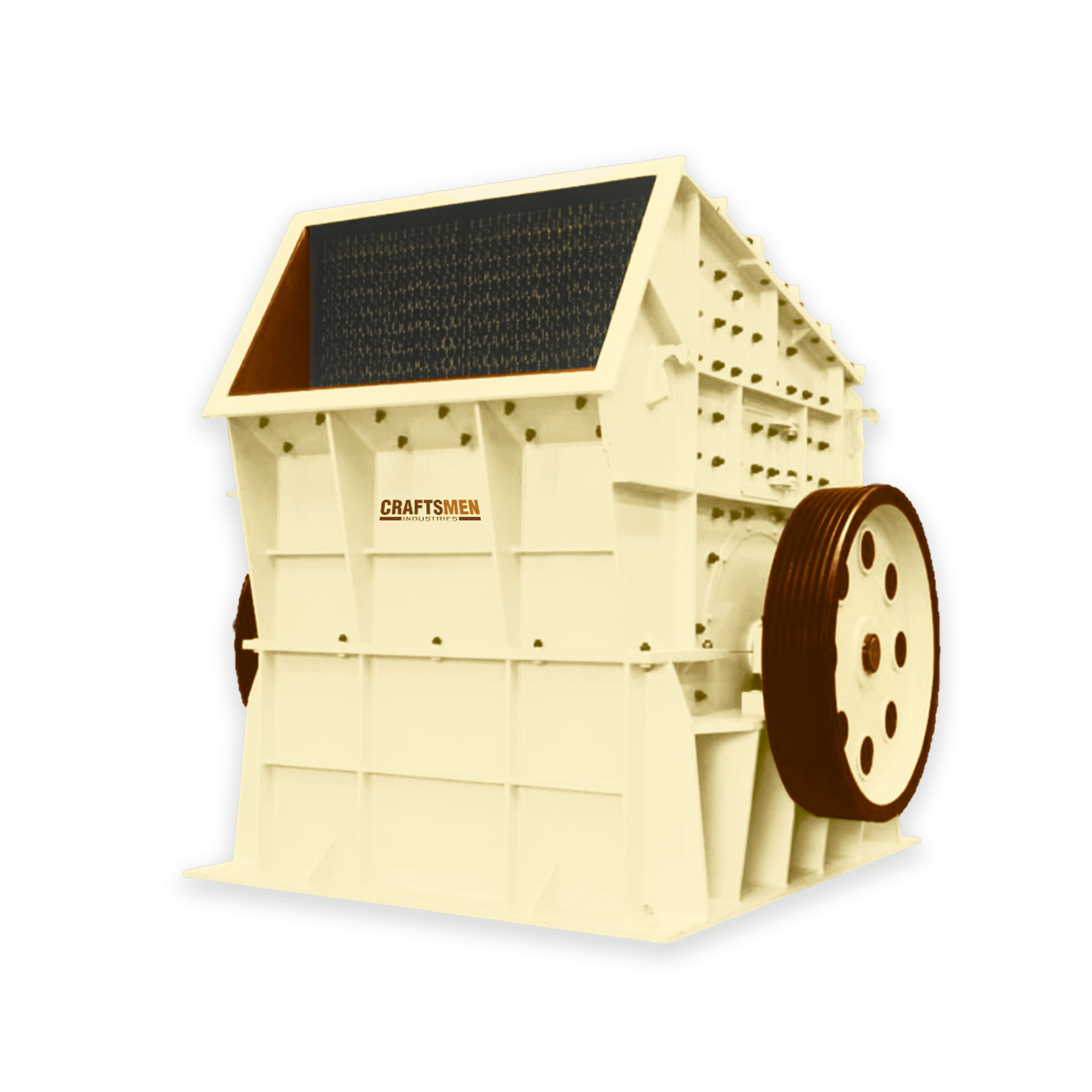

In the realm of jaw crushers, precision and performance are paramount, and when it comes to mastering this craft, Craftsmen Industries stands as a beacon of excellence. Nestled in the historic city of Udaipur, Craftsmen Industries has carved a niche for itself as a premier manufacturer of jaw crushers, showcasing a commitment to quality and innovation.

With a legacy steeped in engineering prowess, Craftsmen Industries has consistently raised the bar in the design and production of jaw crushers. This blog post serves as a testament to their dedication, as we explore five practical and usable tips to optimize the efficiency of Craftsmen’s jaw crushers.

Whether you are operating their machinery or considering an investment, these insights will not only illuminate the path to enhanced performance but also underscore Craftsmen Industries’ position as a trusted leader in the industry.

Join us on this journey as we unravel the expertise behind Craftsmen’s jaw crushers, blending technology and craftsmanship to redefine crushing standards. Discover how these tips can unlock the full potential of Craftsmen’s jaw crushers, turning the act of crushing into a seamless symphony of precision and productivity.

Here are five usable tips for optimizing the performance and maintenance of a jaw crusher:

1.Regular Maintenance Checks:

-Schedule regular maintenance checks to inspect key components such as the jaw plates, bearings, and toggle plate. Replace or repair any parts that show signs of wear or damage promptly.

-Ensure that all fasteners are properly tightened to prevent loose components that may affect the performance of the jaw crusher.

2.Proper Lubrication:

-Lubrication is crucial for the smooth operation of a jaw crusher. Regularly check and replenish lubricants, such as grease, to key areas like the bearings.

-Follow the manufacturer’s recommendations for the type and amount of lubricant to use. Over-lubrication or under-lubrication can lead to excessive wear or other issues.

3.Adjustment of Jaw Crusher Settings:

-Monitor and adjust the settings of the crusher to optimize its performance based on the type of material being processed. This includes adjusting the closed side setting (CSS) and the eccentric throw.

-Ensure that the jaw plates are properly aligned and positioned. Improper alignment can lead to uneven wear and reduced efficiency.

4.Control Feed Rate:

-Maintain a consistent and controlled feed rate to the jaw crusher. A steady and uniform feed helps prevent overloading and ensures that the crusher operates at its optimal capacity.

-Avoid overloading the crusher by adhering to its capacity limits. Exceeding these limits can lead to increased wear, decreased efficiency, and even damage to the crusher.

5.Monitor Wear Patterns:

-Regularly inspect the wear patterns on the jaw plates. Uneven wear may indicate issues with the feeding or the crusher itself.

-Rotate or replace jaw plates as needed to ensure even wear and maximize their lifespan. This can help maintain consistent crushing performance and reduce the frequency of downtime for replacements.

Always refer to the manufacturer’s guidelines and recommendations for your specific jaw crusher model. Consult experts for tailored jaw crusher advice on maintenance and operations for optimal performance. Regular monitoring, maintenance, and adherence to best practices are essential for the long-term efficiency and reliability of a jaw crusher.

Conclusion:

In the realm of jaw crushers, Craftsmen Industries shines as a beacon of excellence in Udaipur. Their commitment to quality surpasses manufacturing, extending to empowering operators and enthusiasts. As we conclude our exploration of five usable tips for optimizing jaw crushers, Craftsmen’s dedication becomes evident. It’s more than machinery; it’s a commitment to knowledge and maximizing potential.