Jaw Cone VSI

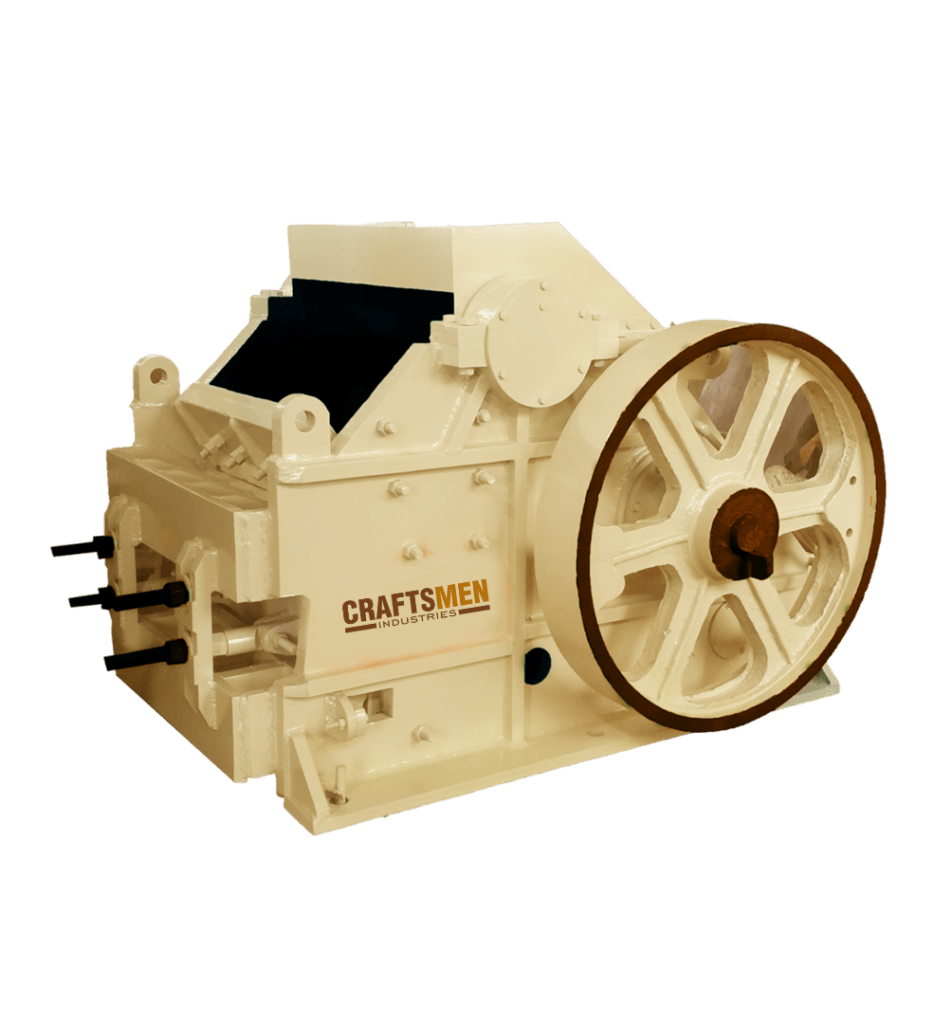

Jaw Crusher

The crushing action in a jaw crusher is achieved by the two jaws compressing the material against each other. As the material enters the crusher, it is gradually reduced in size as it moves down the crushing chamber, eventually being discharged at the bottom as smaller-sized particles. Jaw crushers are capable of handling various types of materials, including hard and abrasive ones like ores, rocks, and minerals.

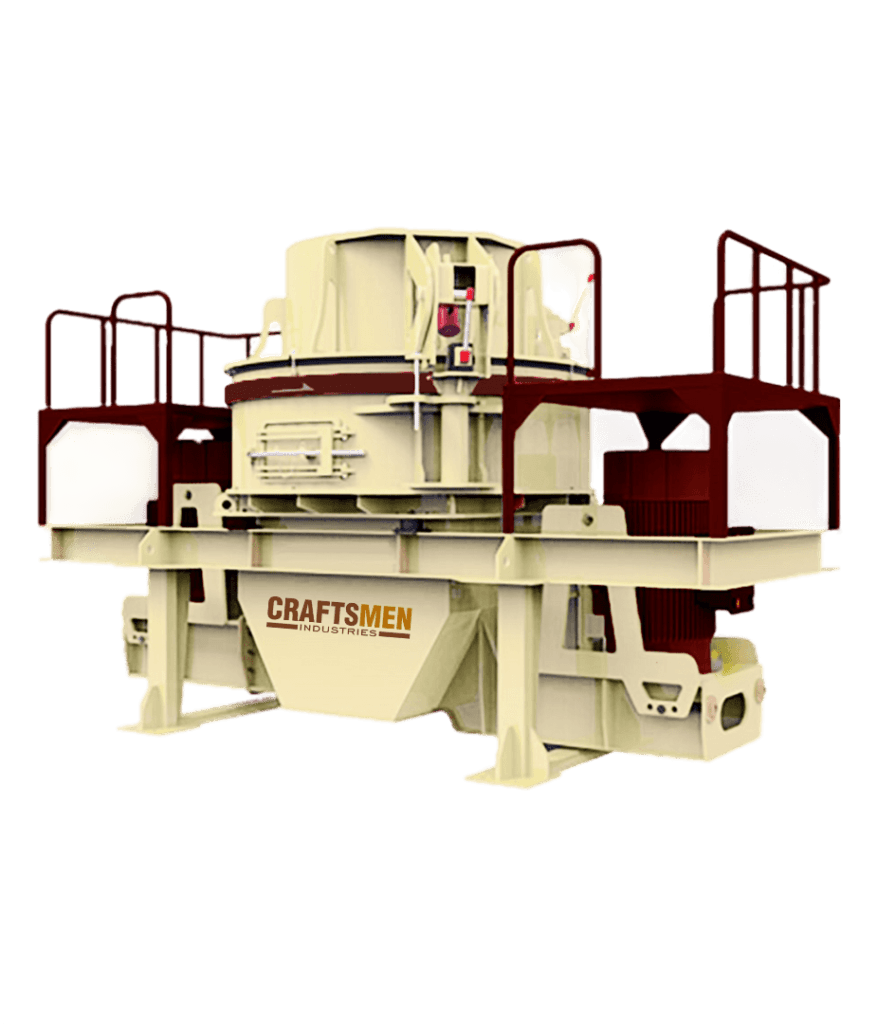

Vertical Schaft Impactor

The VSI crusher, consists of a rotor with a shaft in vertical arrangement. The material enters the interior of the rotor, and when it rotates at high speed, it projects the material towards the exterior where the anvils or impact screens are located. There is a variant in which the material thrown hits an impact chamber filled with the same material to be crushed. Constitute the crushing stone against stone.

Cone Crusher

A cone crusher is a type of mechanical machinery used to crush and reduce the size of various types of rocks and minerals through a process of compression and cutting. It is typically used in the mining and aggregate industries for secondary and tertiary crushing stages.

Here are some key features and aspects of cone crushers: Working Principle: Cone crushers operate by squeezing the material between an eccentrically rotating mantle and a concave (also called bowl liner). As the mantle moves eccentrically, it creates a compression force on the material, breaking it down by applying pressure.